1, engineering explosion-proof safety assessment

New project-on-site inspection and evaluation of explosion-proof safety of new project: issue an evaluation report after evaluation;

Projects that have been put into production —— On-site inspection and evaluation of staged explosion-proof safety of projects that have been put into production;

Reconstruction and expansion project —— Adaptability and conformity between selection and construction of reconstruction and expansion project and dangerous environment ……

2, dust environmental safety assessment and explosion-proof transformation

For: places with dust explosion danger in industries such as steel and food.

Content: According to GB3836, GB12476 and other standards and process flow, identify the sources of combustible dust emission, divide the hazardous areas, and propose the selection and transformation scheme of electrical equipment, which can be implemented.

Inspection and inspection institutions with explosion-proof professional qualifications shall conduct inspection and evaluation according to GB 50257 Code for Construction and Acceptance of Electrical Equipment in Explosion and Fire Hazardous Environment of Electrical Equipment Installation Engineering. Obtain compliance safety evaluation report

3. Gas to electricity

Typical scheme

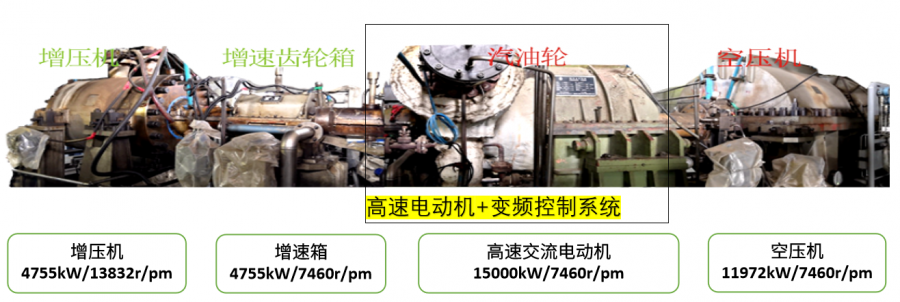

Background: Steam generated by small coal-fired boilers is used to drive steam turbines, and then high-speed air compressors, superchargers, fans and other equipment. In order to solve the environmental pollution problem of small coal-fired boilers, the steam turbine drive is directly changed to high-speed motor drive.

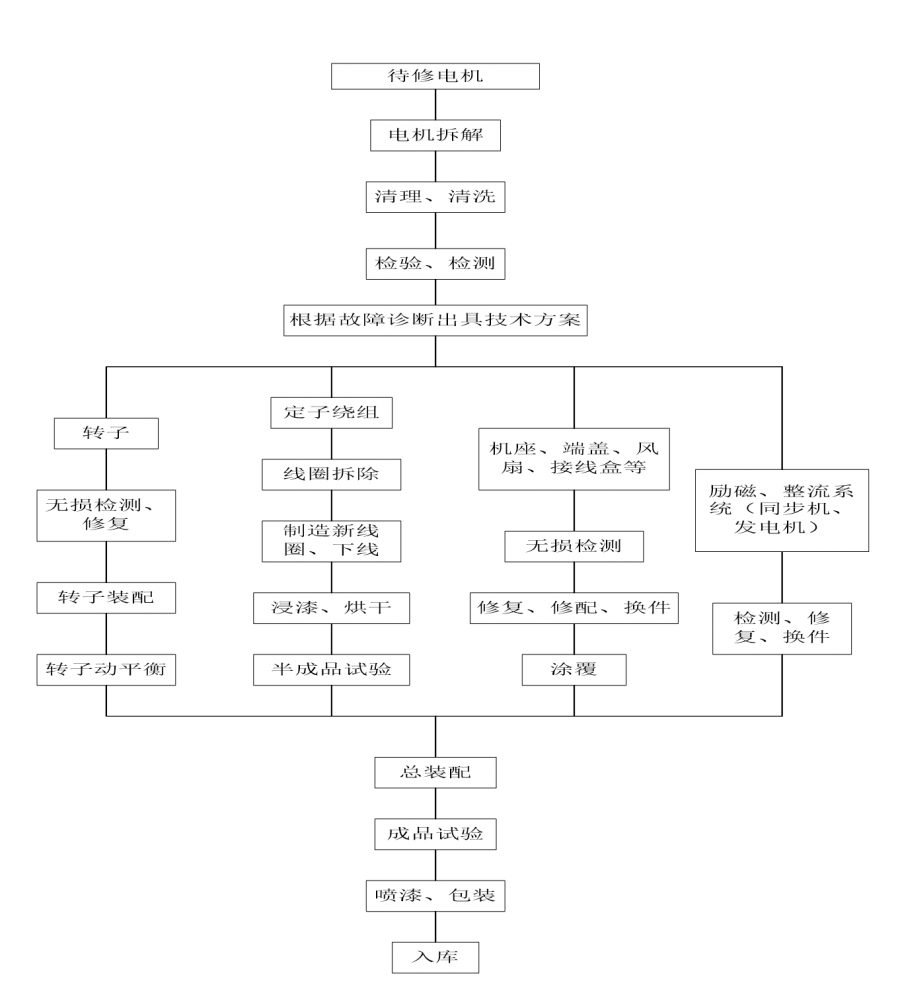

Process flow of motor overhaul

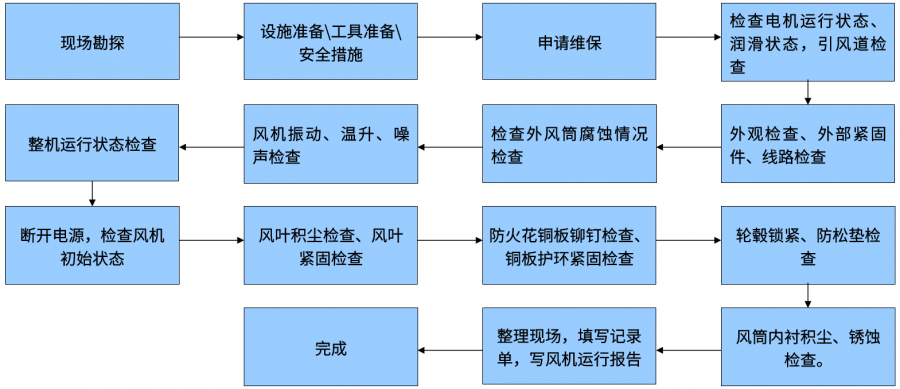

Construction process of maintenance and overhaul of fan